A40, A60, G90 Explained: Be Able To Explain It Like A Pro

Most professionals in the built environment have a general idea what A40, A60, and G90 mean but can you confidently explain it to an architect or contractor which the better choice is for hollow metal doors and frames?

Most professionals in the built environment have a general idea what A40, A60, and G90 mean but can you confidently explain it to an architect or contractor which the better choice is for hollow metal doors and frames?

Here’s your quick refresher to help you sound like the expert they need.

Understanding the Numbers

The numbers tell you the total zinc coating weight per square foot (both sides):

- A40 = 0.40 oz/ft²

- A60 = 0.60 oz/ft²

- G90 = 0.90 oz/ft²

🔑 Higher numbers mean a thicker zinc layer, providing better corrosion resistance but that’s only part of the story. There is more than just the coating weight to consider when selecting the best material for your project.

Let’s Breakdown: “A” vs. “G”

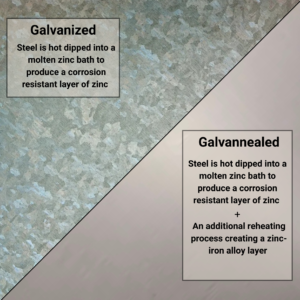

G90 – the G stands for galvanized:

✅ Steel is dipped in a bath of molten zinc, which forms a protective barrier on the surface. This leaves a bright, spangled surface.

✅ It resists corrosion well as bare metal and is typically used in outdoor applications, construction and automotive industries where paint adhesion and/or welding is not an issue.

A40 or A60, the “A” stands for galvannealed.

✅ The steel is also zinc coated as above and then goes through an additional manufacturing step of being reheated, so the zinc bonds with iron, forming a zinc-iron alloy layer.

✅ The result? A matte, uniform surface that is far better suited for paint adhesion and welding.

Why A60 Is the Better Choice for Hollow Metal Doors

At first glance, it might seem as if G90 would be the better choice for corrosive environments due to it’s thicker zinc coating but that is not the case. A60 is actually the smarter specification for painted hollow metal doors and frames. Here are a few reasons why.

- Superior Paint Adhesion: The zinc-iron alloy surface of A60 bonds beautifully with primers and topcoats, reducing risks of peeling and flaking.

- Weldability: The zinc-iron alloy provides an excellent surface for welding. It’s higher melting point and strong adherence during the welding process. The remaining alloy and weld bead better accept primer and paint maintaining the corrosion protection. It also welds more cleanly, safely and produces less zinc fume hazards.

- Durability: Galvannealed coatings are harder and more scratch-resistant than galvanized, ideal for commercial environments.

- Industry Backing: The Steel Door Institute (SDI) states that the galvannealed coating has several advantages compared to the galvanized coating. Read more here… SDI 112-08.